A sign of a poor gunsmith is using normal screwdrivers on a gun. However not all individuals that like guns know the difference between a normal and gunsmith screwdriver. This post will fix that.

I am a kitchen table gunsmith myself, and before I learned about using hollow ground screwdrivers on my firearms I buggered up plenty of firearms.

Normal Screwdrivers are Taper Ground

A normal screwdriver is taper ground. The manufacturer took a shaft of steel, and then smashed the end into a wedge.

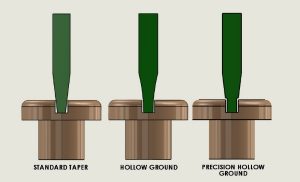

As you can see from the picture below, the tapered shaft on the left does not fully engage with the entire screw slot.

This means that the torque from tightening the screw is unevenly applied. This can damage the screw threads, and is the mark of an inexperience and/or uneducated gun smith.

Gunsmith Screwdrivers are Hollow Ground

In comparison, the screw driver in the middle of the picture is hollow ground and the screwdriver shaft is ground down in a concave shape to allow the entire screw thread to be filled.

In comparison, the screw driver in the middle of the picture is hollow ground and the screwdriver shaft is ground down in a concave shape to allow the entire screw thread to be filled.

The driver transmits the torque to be transmitted evenly. As a result, damage to the screw is prevented. Additionally, a hollow ground screwdriver has a head that is the same diameter of the shaft. Therefore, it will fit down inside of tubes easier.

If you have ever had the wide head of a tapered screwdriver keep you from unscrewing the back of a piece of electronics you will know what I am talking about.

In conclusion, proper tools don’t cost a whole lot more than improper tools (with the case of hollow ground drivers, they cost the same or less) but make your work easier and contribute to a professional repair. I bought my set of screwdriver bits for under $20 online and now I don’t damage anymore gun screws.