Being a carry permit holder I have a thing for gun holsters, being a big guy, I spend a lot of time baking sure that my holsters are comfortable and work well with the clothing I wear. Something I have noticed “gun guys” is that we all have a box of old holsters. The majority of holsters I use on a daily basis are either Kydex or combination’s of both leather and Kydex.

That is no surprise when you look at the benefits of Kydex. Its cheap, rugged, non-marring of your gun’s finish, moldable for good retention, smooth for a consistent draw, and does not react to normal temperatures or gun solvents or oils.

You Need a Press to Work with Kydex

If you want to experiment with kydex you need a kydex press – like all my projects, I wanted something cheap and simple to test out before I invested in quality tools – this post’s kydex press is just such a tool.

Being a DIY enthusiast, it did not take me long to want to try my hand at molding Kydex. For those of you that do not know, Kydex is the trade name for a propriety thermoplastic sheet. It’s rigid and strong, but when heated it becomes pliable. Kydex does not have a memory, so that once it has cooled; it retains the shape it was molded to fit. Kydex is not the only plastic compound that has this property. However, what makes Kydex so useful is that unlike plastics, Kydex doesn’t off gas toxic fumes at forming temperatures.

Tools to Form Kydex

Most people use either an oven or a heat gun. Often I use a goodwill toaster oven. It really depends on the thickness of the Kydex your working with. Also the size of the piece your molding will impact on your heat source. Normally I find the oven works best to begin the project, and I use a heat gun to spot heat for adjustments.

Besides a heat source, gloves, and trimming tools, one of the most basic tools to mold Kydex is a press. A Kydex press normally costs from $80 to $180 depending on size, but it is a simple tool that I decided to make one myself.

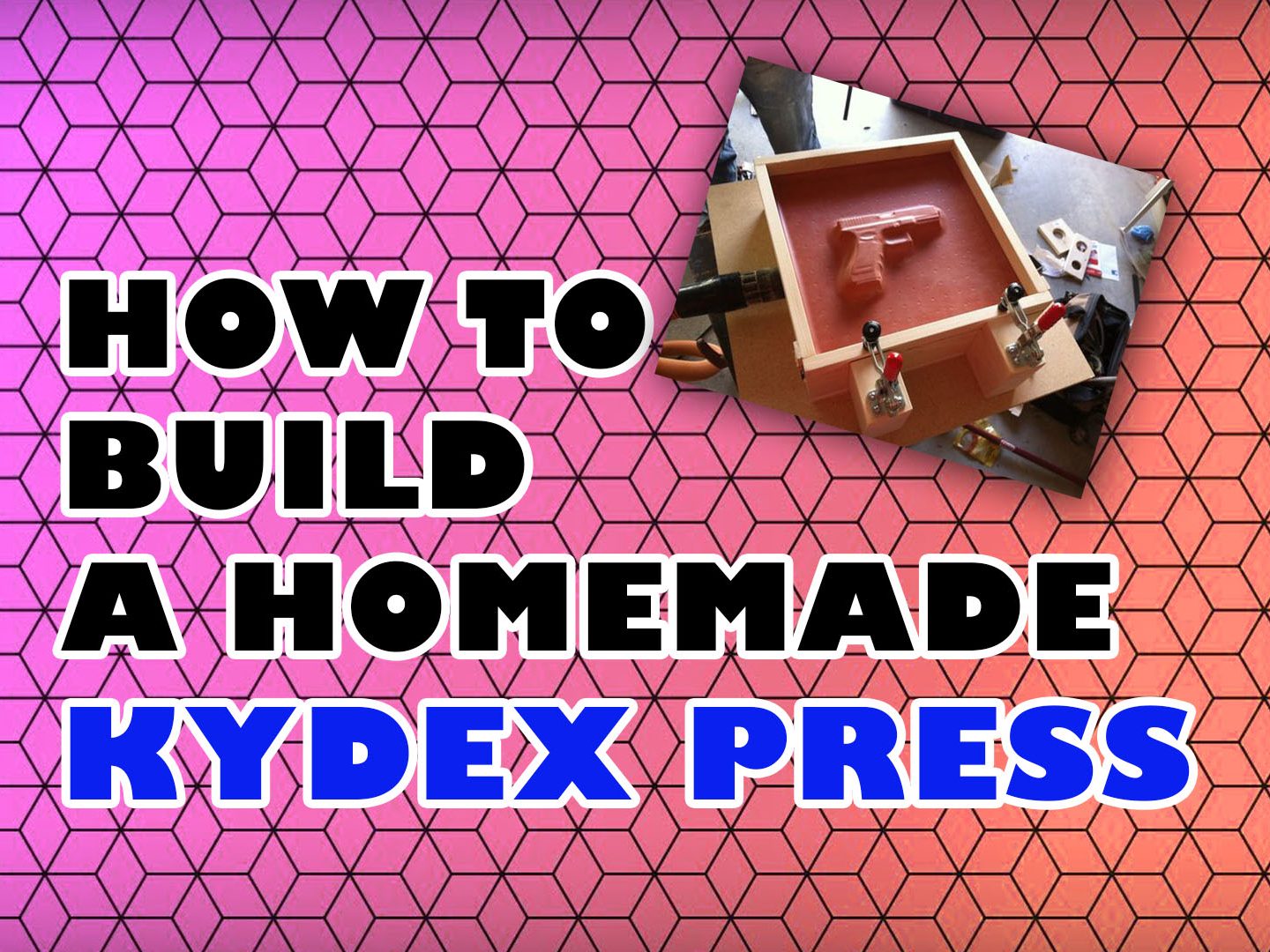

Simple Homemade Kydex Press

At its simplest a Kydex press is a rigid board with a thick piece of foam glued to it as a base, with top made the same way. The heated Kydex is wrapped around whatever it will sheathe, and then sandwiched between the two pieces and then clamped or weighted heavily until the plastic cools.

I went a little more complicated, as I put a set of hinges to connect the top and bottom pieces. I connected them this way because I plan on making knife sheaths. At least until I got enough skill to try more complicated gun holsters. Also, by being connected, it gives me more leverage for clamping.

If I was making a press for larger items like gun holsters I would make modifications. Either I would not add a hinge, or I would make the hinge adjustable.